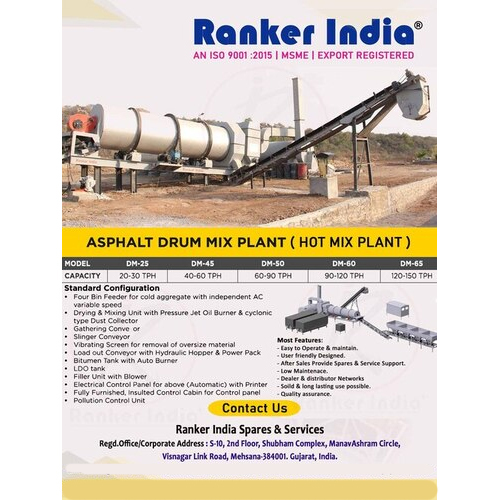

Hot Mix Plant /Drum Mix Plant

Price 3800000.0 INR/ Piece

Hot Mix Plant /Drum Mix Plant Specification

- Noise Level

- 85 dB db

- Fuel Type

- Diesel

- Temperature

- 140 C 165 C Fahrenheit (oF)

- Air Pressure

- 8 Bar PSI

- Working Width

- 2.35 m

- Coverage Area

- Front Width Coverage 2.5 m Square Foot (ft2)

- Hopper Capacity

- 1500 kg Kilogram(Kg)

- Compressor Type

- Air Cooled

- Tank Dimensions (Mm X Mm X Mm)

- 3500 x 2500 x 2800 mm

- Driven Type

- Electric

- Tank Material

- MS Plate

- Hole Size

- 30 mm Millimeter (mm)

- Mount Type

- Stationary / Mobile

- Material

- Mild Steel

- Capacity

- 60 TPH, 90 TPH, 120 TPH, 160 TPH Ton

- Computerized

- Yes

- Automatic Grade

- Automatic

- Vibration Frequency

- 50 Hz Hertz (HZ)

- Drum Diameter

- 2.2 m 2.8 m Meter (m)

- Power

- 55 kW 100 kW Volt (v)

- Size

- Depend on Capacity

- Color

- Yellow and Black

- Weight

- 13 24 Tons Liter (Ltr)

- Dimension (L*W*H)

- 15.2 m x 2.5 m x 3.6 m (approx) Millimeter (mm)

- Operating Ambient Temperature

- -10C to +50C

- Asphalt Discharge Height

- 3.2 m

- Elevator

- Bucket Type with reinforced belt

- Aggregate Feeder

- Four-Bin System with Variable Speed Drive

- Bitumen Storage Capacity

- 8000 Liters

- Control System

- PLC Based Automated Control Panel

- Power Supply Voltage

- 380/415 V, 3-Phase, 50 Hz

- Chassis

- Heavy Duty Fabricated Steel

- Burner Type

- Automatic Modulating Burner

- Filler Storage Capacity

- 500 kg

- Mixing Drum Type

- Continuous Rotary Drum

- Mobility

- Optional Wheel Mounted for easy transport

- Production Rate

- Up to 160 Tons per Hour

- Dust Collector

- Multi Cyclone, Primary and Secondary Dust Collection

Hot Mix Plant /Drum Mix Plant Trade Information

- Minimum Order Quantity

- 1 Number, Number, Number

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Hot Mix Plant /Drum Mix Plant

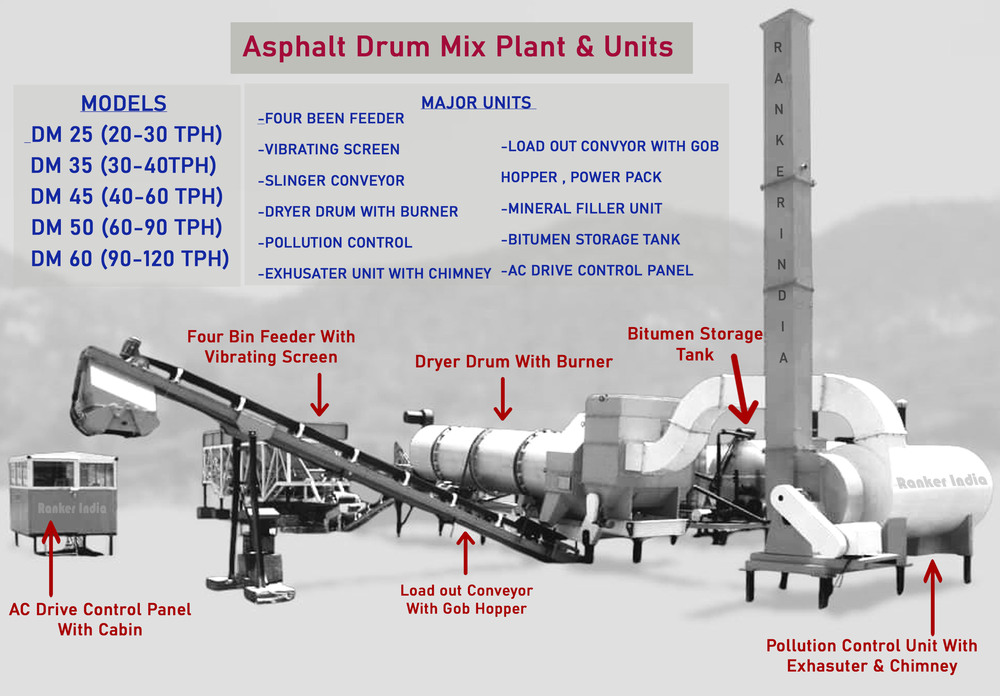

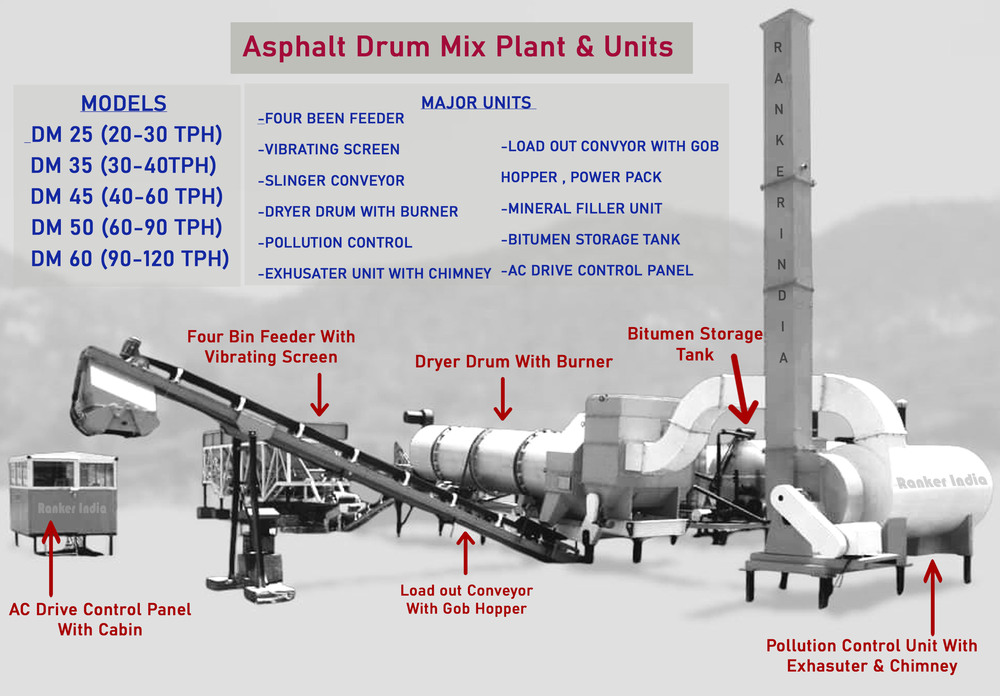

We introduce ourselves as a renowned firm in dealing a wide arrangement of Dryer Drum For Hot Mix Plant. It has a great advantage of a large drying capacity. Provided unit is ideal for drying process. It is a rust proof mechanism which is attached with burner for heating the aggregates. Dryer Drum For Hot Mix Plant aids to separate thehotaggregates in various compartments. It settles down the heavy dust particles with its automatic handling operation.

Technical Specification

| Capacity | As per customize |

| Usage/Application | Road Construction Work |

| Automation Grade | Automatic |

| Material | MS Plate |

| Color | Any |

| Power | 3 Phase |

Advanced Control System

This plant features a PLC-based automated control panel, allowing precise regulation over mixing, feeding, and temperature management. Operators can monitor and adjust production parameters easily, increasing efficiency and safety. Computerized systems optimize resource utilization and minimize manual errors, making operations seamless for both experienced and new users.

Efficient Dust Management

The multi cyclone dust collector employs both primary and secondary dust collection stages, maintaining low emission levels across demanding environments. The system ensures compliance with environmental regulations and protects operator health by trapping fine particles. Its design provides maximum air filtration without sacrificing productivity, benefiting both site safety and equipment longevity.

Robust Mobility & Chassis

Featuring a heavy-duty fabricated steel chassis, the plant is available either stationary or with optional wheel mounting for improved transportability. This allows quick movement between sites for rental companies or contractors with multiple projects. Its compact dimensions facilitate easier setup, and strong construction ensures stability during operation.

FAQ's of Hot Mix Plant:

Q: How does the continuous rotary drum function enhance mixing quality in the Hot Mix Plant?

A: The continuous rotary drum ensures consistent, thorough mixing of aggregates and bitumen by maintaining steady rotation and controlled temperature, which leads to uniform asphalt output suitable for demanding road construction projects.Q: What steps are involved in operating this Hot Mix Plant and starting asphalt production?

A: Operation begins with loading aggregates in the four-bin feeder, followed by automated mixing in the rotary drum. Bitumen and filler are added per recipe, controlled by the PLC panel, with dust managed by multi cyclone collectors. Finished asphalt is discharged at a height of 3.2 meters for convenient loading.Q: When is the best time to deploy the wheel-mounted mobility feature of this plant?

A: The wheel-mounted option is ideal when quick relocation is needed between job sites or when the plant is rented for short-term use. It simplifies logistics, reduces setup times, and minimizes downtime during transportation.Q: Where can this Hot Mix Plant be installed and operated?

A: It is suitable for installation at infrastructure development sites, highway projects, and municipal road works across India, especially where high production rates and robust mixing are required. Its environment tolerance spans -10C to +50C ambient temperatures.Q: What are the benefits of the PLC-based automated control panel for plant operators?

A: The automated control panel allows precise management of the entire mixing process, reducing manual intervention. It increases production consistency, improves safety by automating error-prone tasks, and facilitates real-time monitoring for maintenance and quality checks.Q: Which process ensures efficient dust collection during asphalt production?

A: The multi cyclone dust collector system uses primary and secondary stages to capture airborne particles, ensuring that the environment remains clear of dust and the plant meets regulatory standards for low emissions.Q: In what ways does the Heavy Duty Fabricated Steel chassis support plant longevity?

A: The robust steel chassis provides structural stability, resists wear from heavy loads, and secures all components during operation and transport, ensuring reliable service and a long lifespan for intensive use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Asphalt Drum Mix Plant Category

Four Been Feeder

Price 585000.00 INR / Unit

Minimum Order Quantity : 1 Number, Number, Number

Power : 2 HP

Automatic Grade : SemiAutomatic

Computerized : No

Driven Type : Electric

Chip spreader

Price 285000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : Truck Mounted

Automatic Grade : SemiAutomatic

Computerized : No

Driven Type : Truck Mounted

Asphalt Drum Mix Plant

Price 3500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 340 Watt (w)

Automatic Grade : Automatic

Computerized : Yes

Driven Type : Auto

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS