Four Been Feeder

Price 585000.00 INR/ Unit

Four Been Feeder Specification

- Fuel Type

- Electric

- Mount Type

- Floor Mounted

- Temperature

- Ambient

- Hopper Capacity

- 150 kg

- Noise Level

- Low

- Working Width

- 800 mm

- Driven Type

- Electric

- Hole Size

- Customized

- Type

- Four Beam Feeder

- Material

- Mild Steel

- Capacity

- Customizable (as per requirement)

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Vibration Frequency

- Standard

- Power

- 2 HP

- Size

- Standard

- Color

- Green

- Weight

- Approximately 300 kg

- Dimension (L*W*H)

- 1500 x 800 x 1300 mm

- Chute Material

- Food Grade Stainless Steel

- Application

- Sorting and Feeding Four Types of Grain/Beans Simultaneously

- Feeder Control

- Variable Speed Drive

- Maintenance

- Easy Access for Cleaning

- Power Supply

- Single Phase 220V, 50Hz

- Feeding Mechanism

- Vibratory Feeders

- Usage

- Industrial/Food Processing Plants

- Safety Features

- Emergency Stop Switch

Four Been Feeder Trade Information

- Minimum Order Quantity

- 1 Number, Number, Number

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 10 Per Day

- Delivery Time

- 7 Days

- Packaging Details

- OPEN

- Main Export Market(s)

- Asia, Eastern Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2015

About Four Been Feeder

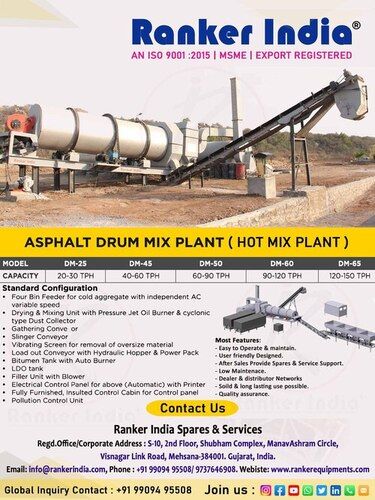

Since 2010 the Ranker India Manufacturing the Road and Civil Construction Equipment. We designed the quality assured & very common useful four bin feeder unit for Asphalt Drum Mix Plant, Hot Mix Plant, Asphalt Batch Mix Plant.

Versatile Vibratory Feeding for Multi-Grain Sorting

The Four Beam Feeder is designed to efficiently sort and feed four types of grains or beans at once, streamlining your food processing or industrial operations. Its vibratory mechanism ensures precise material flow, while customizable capacities and hole sizes adapt seamlessly to diverse production needs. This versatile solution minimizes handling time and increases productivity in environments demanding accuracy and reliability.

Food-Safe and Durable Construction

With a chute crafted from food-grade stainless steel and a sturdy mild steel framework, this feeder guarantees long-lasting performance and hygiene. The use of high-quality materials prevents contamination, allowing safe processing of edible commodities. Maintenance and cleaning are simplified by its accessible design, supporting food safety compliance in every operation.

Operator-Friendly Control and Safety Features

Equipped with a variable speed drive, operators can tailor the feeders output to changing process requirements. An integrated emergency stop switch enhances workplace safety, and the semi-automatic, non-computerized design ensures straightforward, dependable control. Low noise levels and floor-mounting make it suitable for continuous use in busy production floors.

FAQs of Four Been Feeder:

Q: How does the Four Beam Feeders vibratory mechanism improve grain or bean sorting efficiency?

A: The vibratory feeding mechanism enables precise and continuous movement of materials, reducing blockages and ensuring each type of grain or bean flows smoothly through its designated chute. This optimizes sorting and feeding efficiency, even when processing multiple products at once.Q: What types of grains or beans can the feeder handle simultaneously?

A: The feeder is designed to sort and dispense up to four different types of grains or beans at the same time. Its customizable hole size and adjustable settings make it compatible with a wide range of small cereals and legume varieties commonly used in food processing and industrial applications.Q: When should the feeders variable speed drive be used?

A: The variable speed drive allows operators to adjust the feeding rate in real-time, making it useful when processing requirements change due to variations in material type, flow rate, or downstream equipment needs. Use this feature to optimize output and maintain consistent product quality.Q: Where is the Four Beam Feeder typically installed?

A: This feeder is designed for installation in industrial and food processing plants. Its floor-mounted design and standard dimensions (1500 x 800 x 1300 mm) allow it to fit comfortably into existing production lines where multi-type sorting and feeding are required.Q: What maintenance is required for the Four Beam Feeder?

A: Routine maintenance involves inspecting and cleaning the food-grade stainless steel chutes, checking the vibratory drive components, and ensuring the emergency stop switch functions properly. Its easy-access design makes these tasks straightforward, supporting quick turnaround times between batches.Q: How does the emergency stop switch enhance operational safety?

A: The integrated emergency stop switch allows operators to immediately halt all feeder operations in case of a safety concern, helping prevent accidents and equipment damage. This feature is essential for maintaining a safe workplace during high-throughput processing.Q: What are the benefits of using a semi-automatic, non-computerized feeder?

A: A semi-automatic, non-computerized feeder offers reliability, ease of operation, and lower maintenance compared to fully automated systems. It is ideal for facilities where skilled manual oversight is available and allows quick adjustments without complex programming.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Asphalt Drum Mix Plant Category

Hot Mix Plant

Price 3800000 INR / Piece

Minimum Order Quantity : 1 Number, Number, Number

Cooling System : Other, Water / Air

Material : Mild Steel

Automatic Grade : Automatic

Computerized : Yes

Asphalt Drum Mix Plant

Price 3500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Cooling System : Frequency Speed Control

Material : MS Steel

Automatic Grade : Automatic

Computerized : Yes

Chip spreader

Price 285000 INR / Piece

Minimum Order Quantity : 1 Piece

Cooling System : Human Machine Interface

Material : MS Steel

Automatic Grade : SemiAutomatic

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS