Asphalt Plant Spares

Price 10000 INR/ Piece

Asphalt Plant Spares Specification

- Hole Size

- As per OEM Specification

- Temperature

- Max 180C

- Fuel Type

- Diesel

- Hopper Capacity

- 250 kg

- Mount Type

- Stationary

- Tank Dimensions (Mm X Mm X Mm)

- Nil

- Compressor Type

- Rotary Type

- Noise Level

- Less than 70 dB

- Coverage Area

- Variable

- Driven Type

- Electric

- Working Width

- 1200 mm

- Air Pressure

- 6 bar

- Type

- Asphalt Plant Spare Part

- Material

- High-strength Alloy Steel

- Capacity

- Up to 200 TPH

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Cooling System

- Air Cooled

- Vibration Frequency

- 50 Hz

- Drum Diameter

- 1300 mm

- Power

- 15 KW

- Size

- Standard & Custom Sizes

- Color

- Grey/Blue

- Weight

- 350 kg

- Dimension (L*W*H)

- 1300 mm x 800 mm x 650 mm

- Life Expectancy

- Up to 5 years

- Maintenance

- Low

- Application

- Used in asphalt batch and drum mix plants

- Surface Treatment

- Heat treated

- Rotor Diameter

- 475 mm

- Port of Dispatch

- Any Major Indian Port

- Finishing

- Corrosion resistant coating

- Packaging

- Export quality wooden crate

- Compatibility

- Fits major asphalt plant brands

- Lead Time

- 2-4 Weeks

Asphalt Plant Spares Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Western Union, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 , , Piece Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Asphalt Plant Spares

We are able to supply a unique assortment of Batch Mix Plant Spares. These are made with a hot batch mix plants. These are helpful to work in an efficiently. These are compatible with the various kinds of plants. Therefore, provided spares are useful to produce homogenous in an equal size of concrete. Batch Mix Plant Spares are suitable to coat the aggregate with its additives. These are easy to fixed and removed when needed.

Drum Mix Plant Spares

Wet Mix /WMM Plant Spares

Asphalt Batch Mix Plant Spares

HMP Plant Spares

Hot Mix pLant Spares

Unit of the any Hot Mix /Drum Mix /WMM Plant

.

Reliable Compatibility and Superior Construction

Our asphalt plant spares are compatible with both batch and drum mix plants, catering to major brands in the industry. Crafted from high-strength alloy steel and treated for corrosion resistance, these components deliver optimal performance even under rigorous conditions. The heat-treated surface ensures durability and longevity, while the export-quality packaging protects each part during transit.

Enhanced Efficiency and Longevity

Engineered for low maintenance, these spares come with a robust build and advanced surface treatments that extend service life to up to five years. Their semi-automatic operation and standardized sizes, along with the option for customization, facilitate seamless installation and reliable functionality. Operating noise is minimized, and efficient cooling ensures consistent performance for every plant session.

FAQ's of Asphalt Plant Spares:

Q: How do I ensure these asphalt plant spares fit my specific plant model?

A: Our spares are manufactured to fit all major asphalt plant brands, both batch and drum-mix types. We offer standard as well as custom sizes to match your requirements-just provide your plant's specifications during order placement.Q: What are the benefits of the corrosion-resistant coating and heat treatment?

A: The corrosion-resistant coating prevents rust and degradation from moisture or chemicals, while heat treatment enhances the part's structural integrity and wear resistance. Together, they extend the spares' operational life and ensure reliable long-term usage.Q: When can I expect delivery if I place an export order from India?

A: After order confirmation, the lead time is typically 2 to 4 weeks. Dispatch is arranged from any major Indian port in export-quality wooden crates to ensure safe and prompt delivery.Q: Where should these spares be stored before installation?

A: Store spares in a clean, dry place to maintain the integrity of the corrosion-resistant coating and the heat-treated surface. The wooden crate packaging provides protection during transportation and storage.Q: What maintenance is required for these spares during use?

A: These spares are designed for low maintenance. Regular cleaning and inspection for wear are recommended, but no frequent or complex upkeep is needed owing to their durable construction and protective treatments.Q: How does the air-cooled system and semi-automatic grade enhance operation?

A: The air-cooled system efficiently regulates temperature during plant processes, and the semi-automatic grade simplifies operation, promoting safe, reliable, and continuous use in demanding asphalt production environments.Q: Why should I choose your asphalt plant spares over other suppliers?

A: We are exporter, manufacturer, wholesaler, supplier, trader, and service provider in India, offering high-strength alloy steel spares with proven durability, optimized finishing, and export-standard packaging, backed by prompt service and customization options to meet any plant need.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Road Paver Finisher And Parts Category

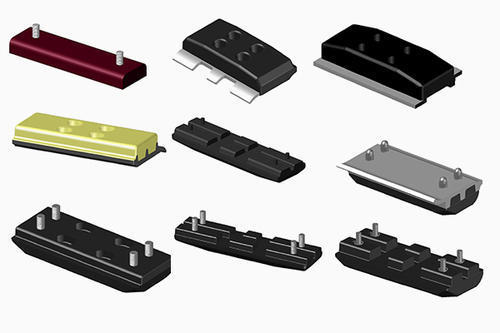

Track Pad For Paver

Price 2000.00 INR / Piece

Minimum Order Quantity : 100 Pieces

Weight : 2 8 Kg per pad (Varies by size)

Computerized : No

Capacity : Standard Load Bearing Capacity

Size : Standard/Custom Sizes Available

Road Paver Spare Parts

Price 10000 INR / Piece

Minimum Order Quantity : 10 Units

Weight : Variable (depends on part)

Computerized : No

Capacity : Standard

Size : As per OEM Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS